Developing an Effective Injury and Illness Prevention Program to Proactively Address Heat-Related Risks

Author: Terry DeRise

Director, Manufacturing at Portacool, LLC

According to the Bureau of Labor and Statistics, in 2015 there were 2,905,900 recordable cases of workplace injuries and 4,836 workplace fatalities. Given that many of these injuries and deaths were likely preventable, the number is appallingly high. Moving forward, evaluating and proactively taking steps to move toward injury and fatality prevention is key. All companies should have an Injury and Illness Prevention Program (IIPP) to help identify hazards in the workplace and protect all employees.

As a basic written workplace safety program, an effective IIPP can improve the safety and health in every workplace. It can be a proactive way to mitigate costs ranging from medical treatment to lost productivity that affect both the employee and the company. Although not required, 34 states in the United States have established laws or regulations designed to require or encourage IIPPs. Fifteen states have mandatory regulations for this documentation. Without a doubt, developing an IIPP can be a beneficial way to protect a company’s employees, reputation and bottom line.

Getting started on developing an IIPP

First, it is important to recognize that an Injury and Illness Prevention Program is not a one-size-fits-all plan. In order to tailor it to a specific company and work environment, an assessment must be made and details such as crew size, work shift length and working conditions (i.e., average temperature of the environment) must be considered. Next, business leaders should assess what they have been doing for safety at their business. Gathering information on current safety rules, policies and practices, will help develop a good foundation on which to build the program.

In order to save time while developing an IIPP, sample models may serve as helpful guides. Many states offer these guides through their regulatory agencies such as the Division of Occupational Safety and Health (DOSH), or Cal/ OSHA, in California. Known to be a trailblazer for developing the most stringent regulations to protect employees, Cal/OSHA serves as a great resource for guidance on IIPP content and structure. Cal/OSHA’s sample model outlines key IIPP elements including responsibility, compliance, communication, hazard assessment, accident or exposure investigation, hazard correction, training, instruction and recordkeeping. Each of these elements directly corresponds with the top IIPP questions that should be addressed in the written plan.

Addressing excessive heat in an IIPP

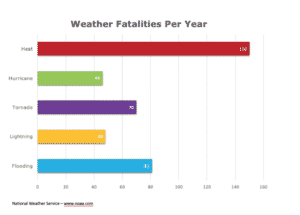

As we move into the summer months of 2018, a company’s hazard assessment should include consideration for the impact excessive heat plays, or could play, in its work environment. According to federal agencies, NASA and NOAA, 2016 was the warmest year on record globally. Overwhelmingly, temperatures and record high days are on the rise. Relative to work-related heat situations, it is estimated that more than 1,300 deaths per year in the United States are due to extreme heat1. Heat related illness and death is preventable, but it takes education, knowledge and the proper tools to be proactive.

Heat is a condition that affects all worksites, whether indoors or out. It is not just a problem that puts outdoor workers at risk on a hot summer day. In addition to the climate, heat can be generated by machinery and increase the average ambient temperature of the surrounding environment. The usage of personal protective equipment (PPE), while helpful and often necessary, can be an additional source of warmth. A hot environment, exacerbated

by the outdoor climate (whether that means that doors have to be left open or that your building isn’t well insulated) can slow down reaction times and create an unsafe environment.

Specific tools to consider adding into an IIPP

Training is crucial to ensure managers and employees understand the true impact of heat. One effective option easily accessed online is the Heat Illness Prevention Program (HIPP). This 25-minute course is specifically designed to help educate employees on how to stay safe during high heat conditions, while complying with state and federal heat illness training requirements. Developed in cooperation with Cal/OSHA, the Occupational Safety Councils of America (OSCA) offers HIPP to provide employee and supervisor education regarding heat illness symptoms, ways to prevent illness and what to do if symptoms occur. For $15 per student, this training program is cost-effective and a relatively small price to pay compared to injury-related costs.

Next, consider what portable cooling solutions can be employed to help bring down the ambient working temperature. When traditional air conditioning is impractical, ineffective or simply too expensive, a great alternative is to utilize a portable evaporative cooler to keep employees cool. Unlike oscillating or mounted stationary fans that simply circulate stagnate, hot air, an evaporative cooler makes the work area more comfortable by actually cooling the distributed air using the all-natural process of evaporation. While evaporative coolers do use water, it is important to note that they are not misters. A variety of sizes of evaporative coolers are available on the market, making it easy to accommodate varying needs while lowering the overall temperature of indoor or outdoor working spaces.

Lastly, if workers will be working outside, it is very important to be prepared to account for the heat index in the summer to accurately reflect the impact of excessive heat. To help plan for outdoor work activities, OSHA and the National Institute for Occupation Safety and Health (NIOSH) have developed the OSHA-NIOSH Heat Safety Tool. This mobile app allows workers and supervisors to calculate the heat index for their worksite, and, based on the heat index, displays a risk level to workers. Placing this in an IIPP provides employees with an easily assessable tool to use daily during extreme heat.

Getting ahead – the IIPP is worthwhile

Workplace safety is a group effort and, when it comes to safety and preventing accidents, planning ahead is key. Implementing an IIPP that addresses a wide variety of risks, including extreme heat, can help assist the team decrease workplace injuries and foster a workplace culture that lends itself to higher productivity, reduced turnover, reduced costs and greater employee satisfaction. It is worth business leaders making the time and investment in these plans to protect their company and employees, while also staying ahead of regulation.

1. Page 6, EPA: https://www.epa.gov/sites/production/files/2016-08/documents/print_heat-deaths-2016.pdf

ABOUT THE AUTHOR

Terry DeRise is the Director of Manufacturing at Portacool, LLC., where he oversees all Portacool portable evaporative cooler manufacturing. DeRise joined the Portacool team in January 2013 as Quality Manager. While working for the company in various other roles, as well as his current, DeRise has made significant improvements in throughput, efficiency and quality of the Portacool manufacturing process. With almost 30 years of military and civilian experience, he leads a team of 150 employees at Portacool’s East Texas manufacturing facility where he is a believer in proactive planning to reduce workplace risks for all employees. For more information or to submit questions, send your email to: support@portacool.com.